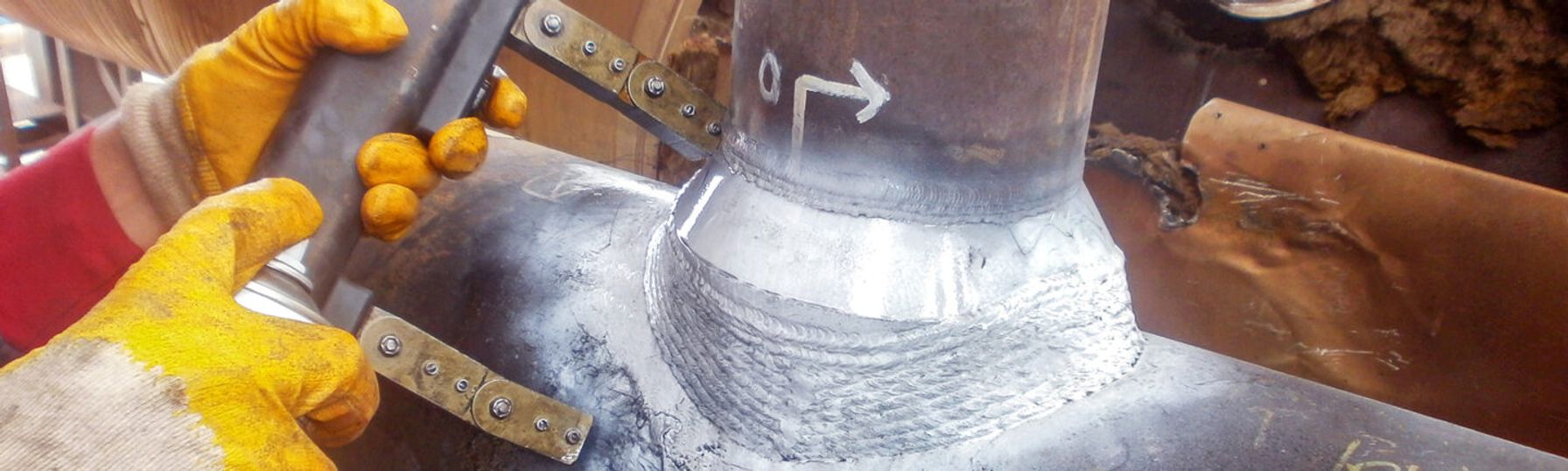

Fabrication Inspection

Structural Steel and Non-Destructive Testing

Ensuring integrity and safety for buildings and infrastructure components

Not bound by industry not bound by geography.

Our inspectors carry multiple certifications allowing them to cost effectively inspect in many roles and have performed services throughout the United States, as well as Europe, Asia, Mexico, South America and Canada.

TRC offers highly skilled and motivated professional materials engineers, nondestructive testing (NDT) technicians and steel fabrication shop inspectors to provide assistance throughout all stages in a product’s life cycle – design, inspection, maintenance, repair and failure analysis.

Typical projects to which our staff are assigned include:

- Bridge fabrication and erection

- Bridges

- Buildings

- Wind Farm Structures

- Highway structures – signage and high-mast lighting

- Pressure vessels and tanks (ASME, API)

Technical staff are certified and qualified to meet the requirements of ASNT Recommended Practice SNT-TC-1A and/or ANSI/ASNT CP-189/ISO 9712.

If you are welding it together, we can help you.

We offer an in-depth knowledge of all relevant codes stipulated by the American Welding Society (AWS), American Society of Mechanical Engineers (ASME), American Petroleum Institute, Steel Structures Painting Council (SSPC), and the American Society for Nondestructive Testing (ASNT).

Whether its understanding service fatigue, selecting the right material or recommending a component for maximum long-term durability – our engineers and technicians are able to provide quick, detailed and cost-effective analysis.

Our associated staff includes the following:

- ASNT Level II/III Inspectors

- ASNT Certified Radiographic Interpreters

- AWS Certified Welding Inspectors

- NACE Certified Inspectors

- Welding Engineers

- PAUT Inspectors

Looking for effective solutions to your problems?

Turn to the experts at TRC.