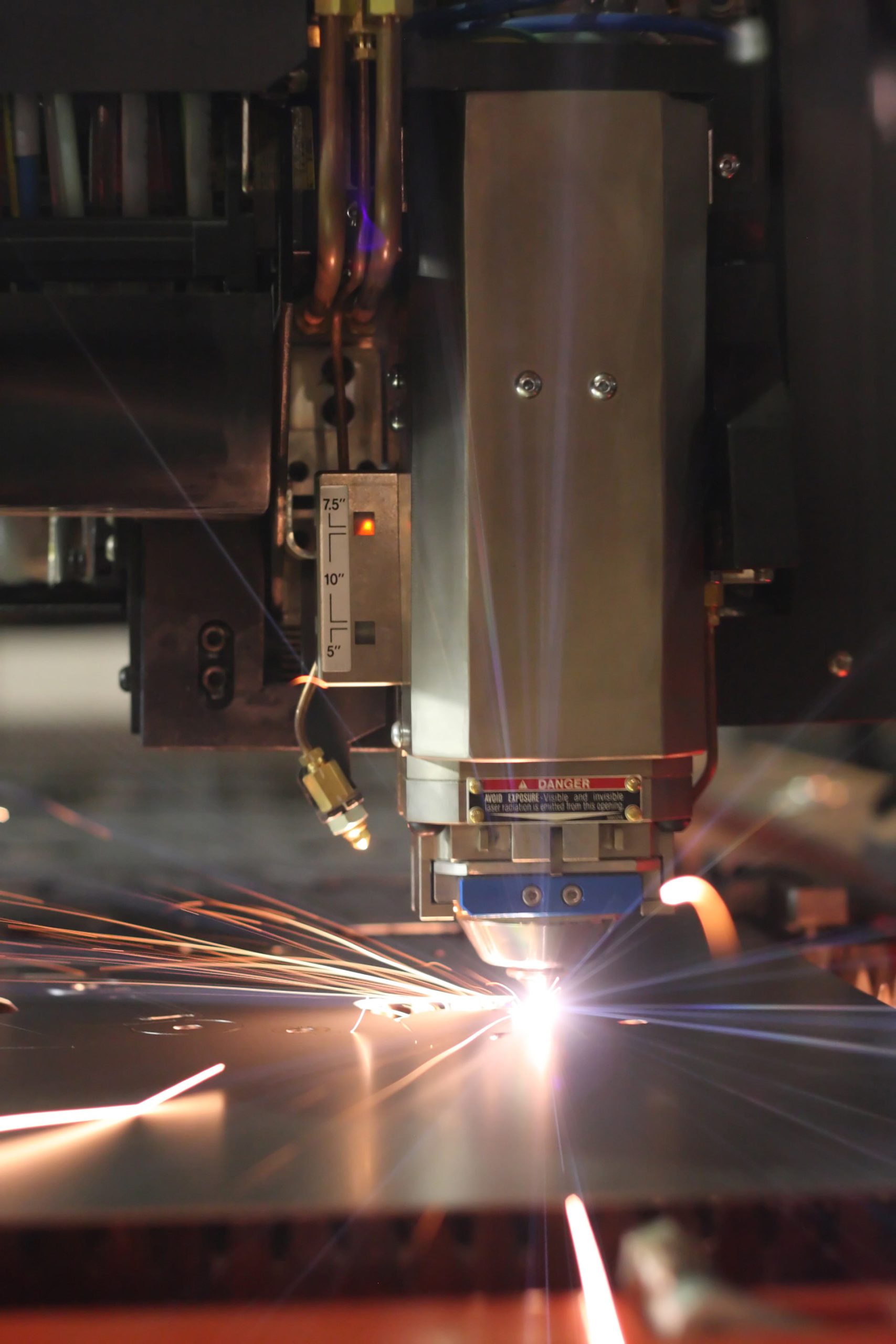

From research and academia to clinical and industrial environments, lasers are precision tools with unlimited potential. A comprehensive laser safety program allows your organization to fully utilize advanced laser technology while minimizing risks that could jeopardize the well-being of your personnel, the integrity of your operations and overall laser-related initiatives.

Without a laser safety program, your organization is at an increased risk of:

- Injury and health risks to personnel and bystanders

- Legal and regulatory violations

- Costly equipment damage

- Reputation damage from laser-related incidents

- Loss of talent due to unsafe working conditions

TRC actively confronts these challenges by implementing proactive and sustainable laser safety solutions.