Author: David McKenzie | May 8, 2018

Michigan has increased efforts to protect its residents from the emerging threat of per- and polyfluoroalkyl substances (PFAS) with a pair of regulatory actions aimed at reducing the presence of these chemicals in the state’s water supply:

- In January the state adopted the Environmental Protection Agency’s threshold for perfluorooctanoate (PFOA) and perfluorooctane sulfonate (PFOS) as the state standard for the acceptable combined concentration in groundwater.

- In late February the Michigan Department of Environmental Quality rolled out the Industrial Pretreatment Program (IPP) PFAS Initiative for wastewater treatment plants to reduce the presence of PFAS in Michigan surface waters due to the discharge of treated wastewater effluent.

Related Services

PFAS History

PFAS – synthetic organic chemicals manufactured for more than 70 years for their unique inert nature as non-stick coatings, stain and water proofing agents, demisting agents in metal plating operations and as fire-fighting foam – are now recognized as an emerging contaminant with the potential to cause significant human health risks. Because of their inert nature, they resist photolytic, biological and chemical degradation, and therefore are found ubiquitously in the environment.

Following the EPA’s Lead

In 2016 the EPA issued a Lifetime Health Advisory (LHA) for two of the most widely detected PFAS – perfluorooctanoate and perfluorooctane sulfonate – and established an acceptable threshold for these compounds in drinking water at 70 ng/L (nanograms/liter, or parts per trillion).

In the wake of that advisory, the State of Michigan created the Michigan PFAS Action Response Team to research, identify and establish PFAS response actions relative to the discovery, communication and mitigation of PFAS.

By adopting the EPA’s LHA for these contaminants, Michigan may now take regulatory enforcement actions against any responsible party that violates the state’s cleanup rules for these contaminants. These enforcement actions will require a responsible party to conduct activities to address the contamination in Michigan to reduce risk to human health and the environment.

The Industrial Pretreatment Program

The state’s Industrial Pretreatment Program is designed to assess whether wastewater treatment plants may be violating Michigan’s Rule 57 Water Quality Standards for PFOS and PFOA.

- The standards for PFOS are 12 ng/L for lakes and streams not used as a drinking water source and 11 ng/L for lakes and streams used as a drinking water source.

- The standards for PFOA are 12,000 ng/L for lakes and streams not used as a drinking water source, and 420 ng/L for lakes and streams used as a drinking water source.

The program requires the following actions be taken by treatment plant operators:

1. Conduct an initial screening of all industrial users in the system that may be significant dischargers of PFOS or PFOA.

2. Develop a plan to monitor all identified potential PFAS dischargers no later than June 29 or submit for approval by May 1 an alternate monitoring strategy and/or request for deadline extension.

3. Perform potential source monitoring in accordance with the developed plan.

4. If sources of PFOS and PFOA are identified, the sources of the PFAS concentrations in the effluent should be addressed through product substitution, operational controls, pretreatment or cleanup of historical contamination. Plant operators must also sample their effluent to assess their discharge relative to PFOS and PFOA

5. Submit by June 29 an interim report of source identification and initial corrective actions proposed or performed

6. After submitting the interim report, continue to address sources and perform additional monitoring as necessary and then submit a summary report by October 26 describing any additional proposed actions.

Because current drinking water standards are higher than the imposed discharge standards, some plant operators may show evidence of high PFOS or PFOA in the effluent simply because the community’s water supply in which it serves contains elevated concentrations of PFOS and PFOA.

What This Means

IPP dischargers should review their operation records for evidence of the use of any product containing PFAS or their use in firefighting operations. They should also work with the local treatment plant personnel so they can gather appropriate samples for PFAS analysis.

If you are a significant discharger of PFAS to your wastewater treatment plant, TRC can help you set up a subsequent confirmation sampling program to verify or refute treatment plant sampling results. If verified, TRC can assist with mitigation plans and remedial measures to address PFAS discharges from your facility.

Next Steps

- Interested in learning more? Contact TRC’s Dave McKenzie at DMcKenzie@trcsolutions.com for more information.

- Check out our corporate brochure to see why TRC has been a groundbreaking engineering, environmental consulting and construction management firm since the 1960s.

- Follow us on Twitter, LinkedIn and Facebook.

- Share your thoughts on this post or ask us a question in the comments section at the bottom of the page.

Sharing Our Perspectives

Our practitioners share their insights and perspectives on the trends and challenges shaping the market.

Advantages of Real-Time, Ultra-Sensitive Chemical Detection: PTR-TOF-MS and Soft Ionization Mass Spectrometry

July 7, 2025

Advanced Proton Transfer Reaction Time-of-Flight Mass Spectrometry (PTR-TOF-MS) and Aerosol Ionization Mass Spectrometry (AIMS) technologies are transforming combustion optimization, ambient monitoring, and emissions monitoring.

Treatment of PFAS to Allow for Beneficial Use of Impacted Dredged Sediments

July 18, 2024

Approximately 200 to 300 million cubic yards of sediment are dredged each year by the US Army Corps of Engineers (USACE) and other federal interests (USEPA, 2007).

Coming at You Fast – The Latest on RCRA and PFAS Regulations

March 1, 2024

The EPA published its Proposed Rule for Listing of Specific PFAS as Hazardous Constituents under the Resource Conservation and Recovery Act (RCRA).

New EPA Rule Impacts PFAS TRI Reporting and Supplier Notifications

November 20, 2023

What Affected Facilities Need to Know About Applicability, Reporting Changes and Deadlines

EPA Proposes Changes to Air Emissions Reporting Requirements (AERR)

August 30, 2023

The EPA is proposing updates to their Air Emissions Reporting Requirements (AERR) through amendments to 40 CFR Parts 2 and 51.

How Does PFAS Contamination Impact the Environment?

August 11, 2023

PFAS are widely used in the production of numerous products. Some PFAS chemicals are the by-product of manufacturing processes. As a result, PFAS contamination is widespread, with PFAS being found nearly everywhere in the world.

Helping Airports Identify and Mitigate PFAS Risks

May 30, 2023

This white paper focuses on some unique strategies and situations we have encountered at some airport sites.

EPA Finds Trichloroethylene Presents Unreasonable Risk in Final Risk Evaluation

April 6, 2023

On Jan 9, 2023, the United States Environmental Protection Agency (EPA) revised the Toxic Substance Control Act (TSCA) to reflect a new risk determination for trichloroethylene (TCE).

Proposed Use of a Hazard Index for PFAS National Primary Drinking Water Regulation (NPDWR)

April 4, 2023

The Proposed MCL and MCLG for the four PFAS, PFNA, PFHxS, GenX, and PFBS, considers their toxicity as additive. The EPA has proposed a HI of 1.0 as the MCL and MCLG for the four PFAS combined.

Proposed MCLGs and MCLs for PFAS

March 15, 2023

Final Regulatory Determination for Contaminants on the Fourth Drinking Water Contaminant Candidate List

QA and Chemistry Services

February 23, 2023

TRC offers many QA and Chemistry services including data usability assessments, limited and full data validation reports, quality assurance project plan preparation, selection of appropriate analytical methodologies and laboratory audits.

PFAS Fate and Transport

February 23, 2023

Understanding PFAS properties and behavior is key to effective detection and remediation.

PFAS Fate and Transport: Conceptual Site Models

February 23, 2023

The conceptual site model describes site-specific sources, release and transport mechanisms, exposure media, exposure points, exposure pathways and routes and potential human and/or ecological receptor populations.

EPA Announces $2 Billion in Funding to Address Emerging Contaminants in Drinking Water

February 14, 2023

Environmental Protection Agency Administrator Michael Regan announced $2 Billion in infrastructure funding to help the nation’s rural water supplies.

EPA Publishes Effluent Guidelines Program Plan 15

February 14, 2023

The EPA announced updated effluent limitations guidelines under Plan 15, focusing on the evaluation and rulemaking process for per- and polyfluoroalkyl substances (PFAS) discharges.

PFAS: Remedial Approaches

February 8, 2023

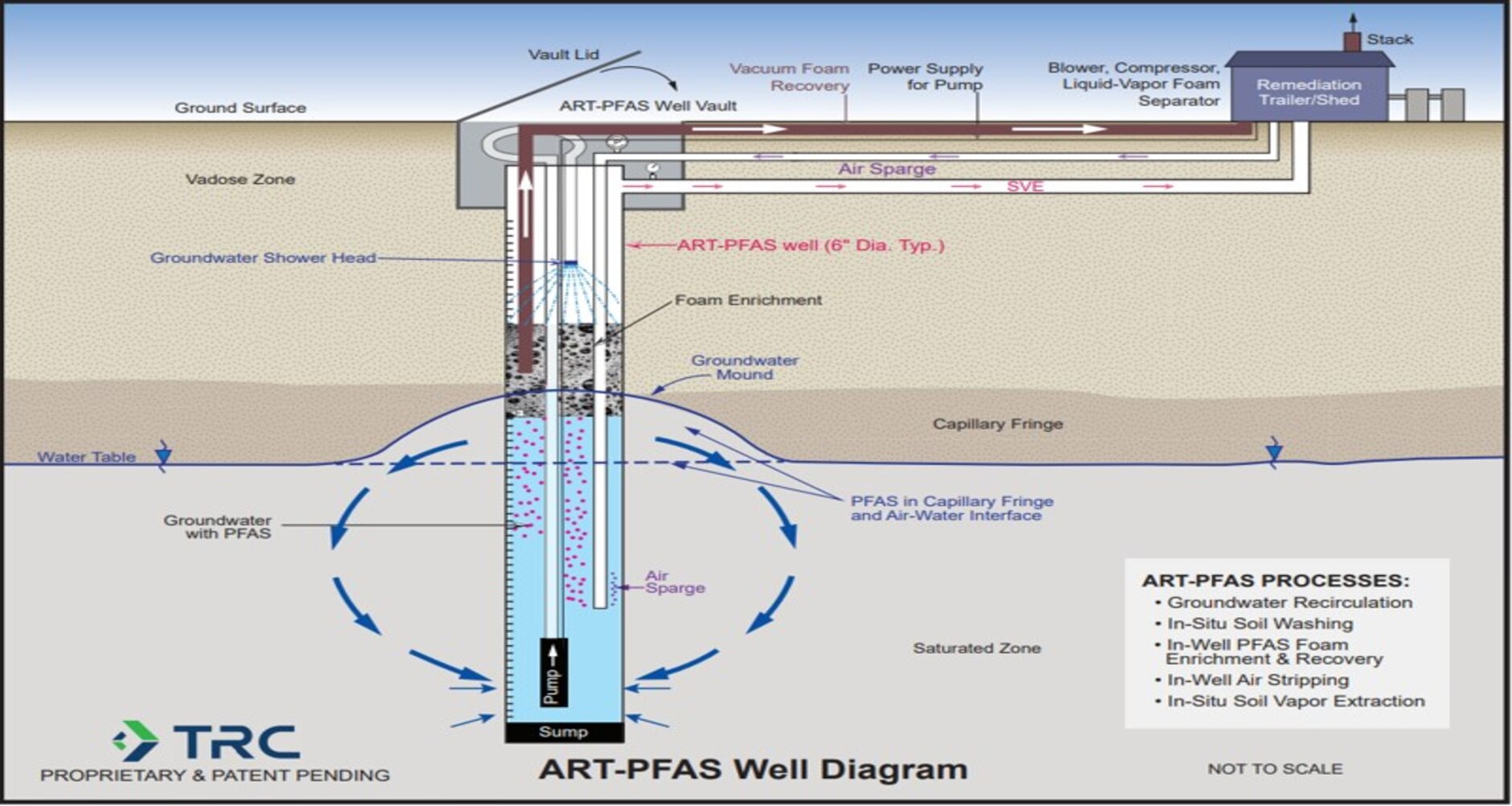

Remediating Per- and poly-fluoroalkyl substances (PFAS) from the soil and water requires effective techniques and innovative technologies. TRC’s experts are well versed in several remediation strategies intended to remove PFAS and prevent re-exposure.

TRI PFAS Reporting Requirements Continue to Expand

January 25, 2023

The list of PFAS for TRI reporting has increased to a total of 189 for reporting year 2023.

PFAS Discharges in NPDES Permits

December 19, 2022

In a follow-up to the EPA Office of Water’s April 28, 2022 memo, EPA released “Part 2″, providing guidance for the NPDES permitting/pretreatment program as it relates to restricting discharges of PFAS to water bodies.

Washington State Establishes PFAS Cleanup Levels

September 21, 2022

The Washington State Department of Ecology (Ecology) recently published a list of 6 PFAS compounds that now have soil and groundwater cleanup levels

New National Emerging Contaminants Research Initiative

September 12, 2022

The Executive Office of the President of the United States announced a National Emerging Contaminant Research Initiative

EPA Issues Proposed Rule Designating PFOA and PFOS as Hazardous Substances

September 7, 2022

The EPA has issued a pre-publication version of a proposed rule to designate two PFAS compounds as hazardous substances under CERCLA.

Five New PFAS Added to EPA Regional Screening Levels (RSLs)

June 24, 2022

EPA announced the addition of five new PFAS to the list of Regional Screening Levels (RSLs)

EPA Announces Updated Drinking Water Health Advisories for Four PFAS Chemicals: PFOS, PFOA, PFBS, & GenX

June 24, 2022

On June 15, 2022, the EPA released updated Health Advisory Levels for four per- and polyfluoroalkyl substances (PFAS) in drinking water

Integrating Sustainability, Digital Connectivity and Design Optimization in Wastewater Treatment Systems

June 20, 2022

Some organizations rarely think about water and wastewater treatment, until there is a problem. American industry depends on the ability to treat wastewater discharges while complying with regulatory standards and addressing emerging contaminants. If wastewater treatment fails, our environment is negatively impacted, and companies are exposed to shutdowns, delays and fines.

Worst Case Discharges of Hazardous Substances – Proposed Rule

May 25, 2022

In compliance with the Clean Water Act (CWA), the U.S. Environmental Protection Agency (EPA) recently proposed a new rule for onshore non-transportation-related facilities requiring specified facilities to plan for worst case discharges (WCDs) of CWA hazardous substances that could cause substantial harm to the environment.

PFAS Discharges and NPDES Permits

May 25, 2022

On April 28, 2022, the U.S. Environmental Protection Agency’s (EPA) Office of Water released a memo addressing the use of National Pollutant Discharge Elimination System (NPDES) permits to restrict per- and poly-fluoroalkyl substances (PFAS) discharges to water bodies.

EPA Proposes Aquatic Life Criteria for PFOA and PFOS

May 25, 2022

On May 3, 2022, under the Clean Water Act (CWA), the United States Environmental Protection Agency (USEPA) proposed the first aquatic life criteria for both short-term and long-term toxic effects from Perfluorooctanoic Acid (PFOA) and Perfluorooctane Sulfonic Acid (PFOS).

SEC Releases New Proposed Rules Requiring Public Companies to Disclose Climate Risks

April 12, 2022

On March 21, 2022, the U.S. Securities and Exchange Commission (SEC) issued its proposed rules for The Enhancement and Standardization of Climate-Related Disclosures for Investors which would require public companies in the U.S. to disclose information in their annual financial reports.

PFOA & PFOS As CERCLA Hazardous Substances: What Does This Mean and How Can You Be Prepared?

February 17, 2022

A plan to designate two per- and polyfluoroalkyl substances (PFAS) as “hazardous substances” under CERCLA was recently submitted by the EPA.

New Phase I ESA Standard Will Affect Environmental Due Diligence

January 25, 2022

After years of review, revisions and discussions, the new ASTM E1527 Phase I Environmental Site Assessment (Phase I ESA) standard has been published. The new standard includes updates to definitions, clarifications on processes and requirements, and guidance for emerging contaminants.

Fifth Unregulated Contaminant Monitoring Rule Lists 29 PFAS

January 21, 2022

EPA published fifth Unregulated Contaminant Monitoring Rule as required every five years and 29 of the 30 contaminants listed are PFAS.

Need help collecting PFAS samples for NJDEP deadline December 15?

October 7, 2021

NJDES Category B or L Industrial Permit holders – If you haven’t obtained your first PFAS sample yet, time is running out. All New Jersey Pollutant Discharge Elimination System (NJDES) Category B or L Industrial Permit holders are required by the New Jersey Department of Environmental Projection (NJDEP) to collect two representative effluent samples, taken 30 days apart, to be analyzed for PFAS by an approved laboratory and submitted to them by December 15, 2021.

Interpretation of “Waters of the United States” (WOTUS) Reverts to Pre-2015 Regulatory Definition

September 29, 2021

Environmental Protection Agency (EPA) and U.S. Army Corps of Engineers (ACOE) revert to pre-2015 regulatory program definition of “Waters of the United States.”

EPA Solicits Comments on PFAS Discharges in Five Point Source Categories

September 23, 2021

EPA solicits comments in five point source categories (PSCs) in the manufacture, use, treatment and discharge of PFAS.

PFAS Air Emissions Standards and Trends for Summer 2021

August 17, 2021

Environmental impacts of PFAS in ambient air leads to states implementing PFAS air-related thresholds.

Cryptocurrency: The Environmental Threats and Opportunities

August 9, 2021

Cryptocurrency (also known as crypto) is taking the fintech industry by storm, despite the economic experts who still dismiss it as a viable form of currency. Although often criticized for this volatility, whistleblowers are also further shining a light on the severe toll that these digital currencies are taking on the environment.

TRC Colorado PFAS Regulatory Update

July 21, 2021

Update on Colorado’s recent policies and plans to regulate new and historical discharges of per- and polyfluoroalkyl substances (PFAS) into the environment.

2021 EPA TRI Reporting Requirements for Natural Gas Processing Facilities

July 12, 2021

Indication EPA finalizing a rule to add natural gas extraction or processing plants to EPCRA Toxics Release Inventory (TRI) reporting.

Implementing bioremediation at environmental cleanup sites: TRC experts weigh in at leading industry conference

May 17, 2021

TRC experts make several presentations at the Battelle conference about innovative approaches they have developed for implementing and monitoring bioremediation and the use of naturally-occurring or deliberately-introduced micro-organisms to break down environmental pollutants.

Interim Guidance on Destruction and Disposal of PFAS & Materials Containing PFAS

February 19, 2021

Interim Guidance from EPA identifies 6 materials that use or manufacture PFAS and approaches for disposal.

EPA continues to aggressively address PFAS wastewater with two new strategies

January 4, 2021

EPA takes steps toward PFAS wastewater and storm water permitting, and analytical methods for testing.

TRC Companies Inc. Acquires 1Source Safety and Health

November 11, 2020

TRC Companies (“TRC”), a leading technology-driven provider of end-to-end engineering, consulting and construction management solutions, has acquired 1Source Safety and Health, a firm that provides management consulting services in areas such as indoor air quality, asbestos management, industrial hygiene and safety management systems.

Ecological Risk of PFAS from AFFF-Impacted Sites

June 30, 2020

The facts on evaluating exposure to wildlife

TRC’s Reporting Tool Can Help Identify New PFAS under the TRI

May 19, 2020

While utilities often work in technical silos, NERC auditors are trained to cross check compliance evidence and data between interrelated standards.

David McKenzie

David McKenzie is a senior engineer in TRC’s Engineering, Construction and Remediation (ECR) Practice. He has more than 25 years of environmental consulting, design and system operations experience at active and closed industrial facilities. His remediation responsibilities have included site investigations and assessments; pilot testing; conceptual and final design; construction; start-up; operation and maintenance; system optimization; and management. Other efforts have included industrial wastewater design and optimization, and off-gas treatment system design and operation. Additional responsibilities include the preparation and certification of spill prevention, control, and countermeasures (SPCC) plans; preparation of subsurface investigation reports; underground storage tank (UST) closure reports; conceptual remedial design reports; permit applications; bid documents; and design drawings and specifications.