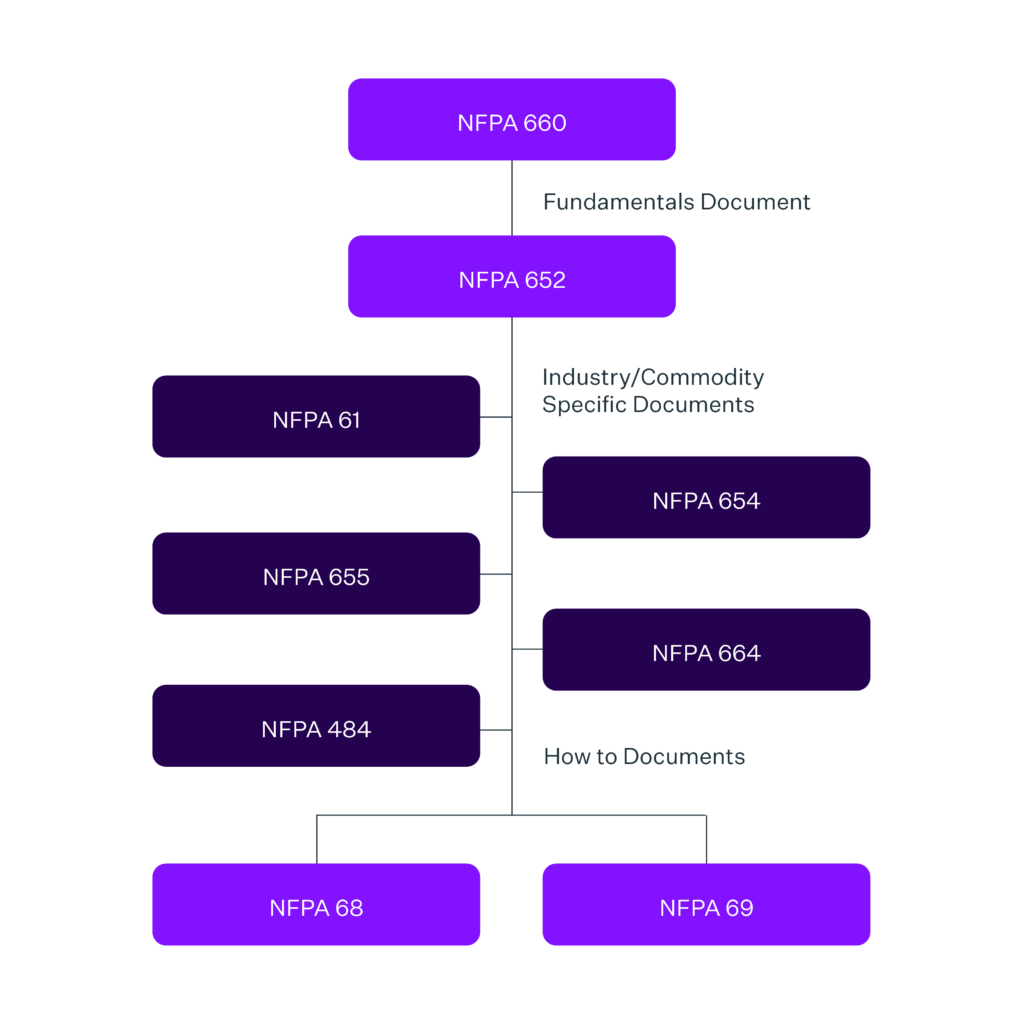

The National Fire Protection Association (NFPA) has consolidated its combustible dust standards into one single, comprehensive standard- NFPA 660- that addresses fundamentals, industry and commodity specific requirements and compliance how-to documentation. NFPA 660 will make it easier for all industries to manage dust related hazards making for safer work environments.

NFPA 660, Standard for Combustible Dusts and Particulate Solids, provides safety requirements for all combustible dusts and particulate solids to help prevent property loss, injuries and fatalities from associated hazards. The consolidated document includes:

- Requirements from the industry or commodity-specific standards that were deemed to be fundamental

- Consistency in definitions and terminology

- Additional requirements for operational readiness reviews

- New requirements for evaluation of self-heating, thermal instability, water reactivity and chemical reactivity hazards

- Qualifications for a Dust Hazard Assessment that “shall be performed or led by a qualified person who possesses documented experience and education regarding methods for performing a DHA as well as the assessment and identification of mitigation or elimination options for the fire, flash fire, explosion and related hazards of the specific type or types of combustible dusts involved in the facility”

- Level of protection provided by flame-resistant garments

- Elements of general safety training and job-specific training and frequency of refresher training

- Requirements for bonding and grounding of housekeeping equipment

- Resistance limits for flexible connectors

- Industrial hygiene exposure limits have been referenced for the recirculation of dust collector exhaust to buildings

NFPA 660 provides a comprehensive framework for safer work environments by preventing dust related fires and explosions. The consolidated standard requires management of combustible dust hazards across a diverse set of industrial operations – both existing and emerging, by standardizing the following key components of an effective dust safety program:

- Risk Assessment and Hazard Identification

- Prevention and Control

- Housekeeping and Maintenance

- Training and Education

- Emergency Response and Preparedness

A Dust Hazard Analysis (DHA) is required to be conducted for all facilities handling combustible dust and must be reviewed and updated every five years.

Next Steps: TRC Can Help

TRC has been working with process operations and facilities with a range of various processing techniques and materials such as agricultural and food products, plastics, wood, chemicals, rubber and powdered metals to mitigate the risk of combustible dust since the 1990s, well before this issue became a priority for the Occupational Safety and Health Administration (OSHA). We have helped facilities act to prevent fires and explosions from occurring, rather than dealing with the consequences of inaction. TRC has assisted clients with risk assessment (DHAs), interpretation of industry guidance and standards, evaluation of control options, and implementation of mitigation measures and work practices.

Related Services

TRC’s Risk Factor Newsletter

Maintaining a safe workplace is key to building a resilient and successful organization. Learn how to navigate the many health and safety risks that your business may face by subscribing to our newsletter.