As extreme weather events increase and installation costs decrease, moving to underground distribution systems is becoming a popular way to prevent power outages. Undergrounding improves system reliability by replacing existing overhead lines with new underground lines, and by installing distribution automation (DA) facilities on other circuits. General concerns about underground cable life coupled with historically lower costs for overhead construction have traditionally led to most facilities being installed overhead. However, over the last decade there have been significant improvements in installation methodologies, equipment manufacturing processes, and the materials used for component construction. Now, the expected useful life of underground cables is up to 60 years, making it an increasingly attractive and practical solution. So, how do you determine if undergrounding is the right solution for your power system?

“To determine if undergrounding is the best approach for your system, start by evaluating the pros, cons and alternatives.”

Chris Fluke

VP Distribution Operations

Estimate Costs and Alternatives

It’s important to consider alternatives to undergrounding before proceeding with a project. First, consider the cost-benefit to continue maintaining the existing overhead system with current maintenance practices and addressing circuit reliability issues as they arise. The downside to this alternative is it only provides minimal “as- needed” improvements to the system. These incremental changes may not result in a significant enough increase in system reliability. Furthermore, this incremental approach still has its own associated costs, like pole replacements.

If temporary faults from vegetation have been a major issue, another option is to expand the existing Right-of-Way to clear additional vegetation and/or increasing the frequency of the trim cycle. The downside to this option is often the cost of the additional easements, the cost of more frequent line clearance, and the negative impacts to aesthetics, which could upset landowners.

Lastly, another alternative is to rebuild overhead distribution lines with taller and stronger poles coupled with larger and stronger conductors, which would reduce the impacts of storms and decrease outages during certain weather conditions. However, a hardened system can have a negative impact on restoration times themselves depending on the storm. A weather event that may now break the conductor and require a splice could potentially break poles with a hardened system, causing extended outages.

Key Undergrounding Project Steps

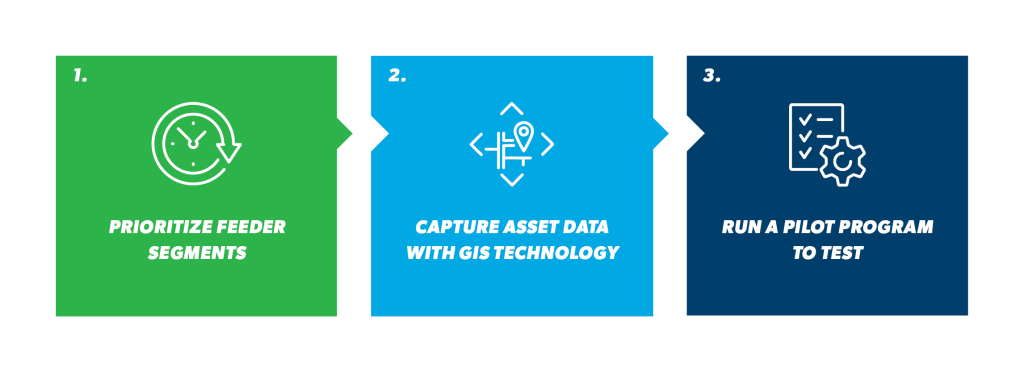

If after careful consideration of all the positives and negatives to each project alternative undergrounding is still your best option, consider the following steps for success.

1. Prioritize Feeder Segments

The first step to successful undergrounding is to identify and prioritize the overhead circuits that will provide the maximum reliability benefit for the cost investment of undergrounding. To do this, it’s important to analyze outage data from previous years. This can be done by extracting the length of each segment of distribution circuit from your designated area’s GIS to determine the total length of line, cross country length, the age of the conductor, the number of phases, and the total connected transformer kVA. A “prioritization matrix” can then be developed using these factors, along with conductor size. After this is done, and calculations for the reliability cost are made, you can now sort your circuits by weighted parameters determined by your internal priorities — such as annual trimming cost and estimated cost to rebuild lines — helping you determine which circuits to prioritize in undergrounding.

2. Capture Asset Data with GIS Technology

In order to become as efficient as possible in both the actual field design and the creation of construction packets for undergrounding, facilitating asset data capture through proprietary and open-source GIS applications is important. These GIS applications, coupled with a variety of GPS technologies, ensure accurate and precise data capture, data transfer, data quality assurance and control, and tailored design creation and reporting.

For any project, having the ability to remain flexible is crucial to its success when it comes to choosing GIS software, evaluating the integration needs, and implementing complex customization requirements. The ability to capture accurate and precise asset locations along with their related information is paramount for the scope of larger undergrounding projects.

3. Run a Pilot Program to Test

Running a pilot program, which can often be completed with existing internal resources, can offer insight about what to expect in the “full production” years of undergrounding. A pilot program will provide insight into landowners’ response to the undergrounding process. It’s important to gauge how open landowners are to certain aspects of the project, like granting easements for the purposes of construction. Pilot programs also help reveal where landowners might run into issues with undergrounding, like trouble with contacting local electricians to convert their meter bases from overhead to underground.

Positive Impacts of Undergrounding

TRC has used these undergrounding strategies in many successful projects on behalf of our clients. In one substantial project, we supported a major Midwestern utility company underground over 1,000 miles of overhead distribution lines located in a heavily forested area to reduce outage duration times. Since the project’s beginning several years ago – and at a pace of approximately 200 miles per year – we were able to lower outage duration times from over 140 minutes per year to less than 7 minutes per year; a 96% improvement.

“Historically, undergrounding was often considered cost prohibitive, but extreme weather events, decreasing installation costs and the significant reduction in outage duration times, more utilities are weighing the cost-benefit analysis of selective undergrounding projects.”

Christopher Fluke

VP Distribution Operations

Next Steps

If you need to move your distribution system underground, TRC has the knowledge and expertise to guide you through every step of the process. From analyzing outage data to prioritize which overhead segments need undergrounding, to choosing a GIS software through evaluating integration needs, to conducting a pilot program, TRC is ready to assist you with any and all aspects of undergrounding you need. Contact our expert below to learn more.