Digital field execution uses mobile tools and real-time data to plan, track and document work directly from the job site. It replaces paper processes with connected, streamlined workflows for faster, more accurate field operations.

Walk onto almost any Transmission and Distribution (T&D) or infrastructure job site and you’ll see a familiar pattern. Crews working with outdated drawings, supervisors piecing together updates from texts and PDFs and leaders making decisions based on information that’s already old. These everyday gaps compound into schedule delays, safety risks, quality issues and costly rework.

To close these visibility gaps and bring true control back to the field, organizations are increasingly embracing digital transformation in field construction management, a shift that connects teams, streamlines data and strengthens every stage of construction project delivery.

What Digital Transformation Means for Field Construction

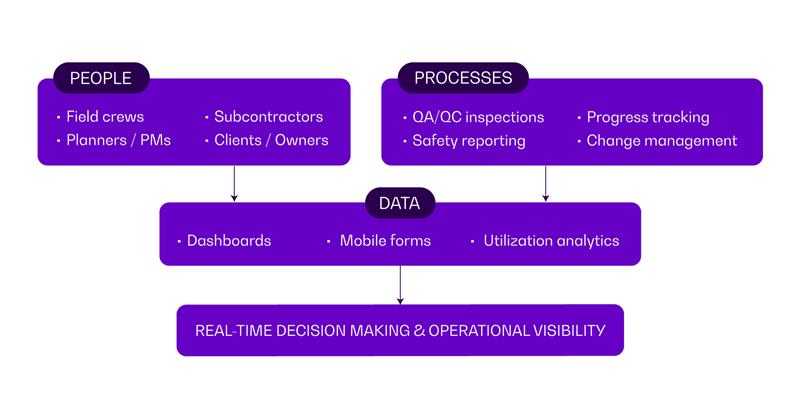

The goal of digital transformation is to eliminate the operational disconnect between the field and the office. When field data becomes real-time, structured and accessible, job sites shift from fragmented execution to highly coordinated, intelligence-driven environments.

Digital transformation in Field Construction Management represents a strategic evolution in how projects are planned, built and monitored. It strengthens safety, improves quality, increases productivity and ensures more predictable delivery across complex T&D and infrastructure programs.

Key objectives of digital field transformation include enhanced visibility, increased efficiency, strengthened quality and safety, optimized resources and improved collaboration.

What Digital Transformation Delivers

A digitally enabled field execution model drives measurable improvements across key performance indicators (KPIs) such as project schedule adherence, cost efficiency, safety and quality compliance, productivity and resource utilization, ensuring projects are delivered more predictably and efficiently.

1. Safety and Quality Excellence

Safety and quality improve when job sites operate with consistent, structured processes:

- Standardized QA/QC forms

- Real-time redlines and digital as-builts

- Predictive safety insights

- Automated tracking of certifications and workforce qualifications

This integrates both operational quality and workforce readiness into a single intelligent workflow.

2. Real-Time Visibility Across Field Operations

Interactive dashboards provide immediate insight into:

- Safety trends

- Progress and productivity

- Crew readiness and utilization

- Material availability and delays

This replaces guesswork with real, actionable data across regions, crews and project types.

3. Efficiency Through Automation and Standardization

Digital workflows reduce the administrative burden that slows field execution:

- Digital forms instead of paper checklists

- Photo-verified inspections

- Automated approvals and routing

- Mobile-first reporting

- Alerts for non-conformance, incomplete tasks, or safety issues

These efficiencies alone reduce documentation time by more than a third.

4. Resource Optimization and Workforce Readiness

Digital field systems enhance construction execution by ensuring the right people with the right skills are deployed at the right time.

Integrated employee profiles store:

- Safety performance

- Certifications and training

- Skill sets and tenure

- Project history

This prevents delays caused by expired certifications, mismatched assignments or inadequate staffing.

Predictive resource forecasting further reduces:

- Idle equipment

- Overstaffing

- Workforce bottlenecks

- Onboarding delays

5. Stronger Client and Contractor Collaboration

Cloud-based platforms unify communication across all stakeholders speeding up approvals, change orders, RFIs and compliance documentation. Approvals that once took weeks drop to less than 48 hours.

Operational Transformation: Before vs. After Digital Adoption

| KPI | Before Digital Transformation | After Digital Transformation |

| Progress Tracking | Manual, inconsistent | Real-time dashboards & mobile updates |

| QA/QC Documentation | Paper checklists | Digital + photo evidence |

| Safety Reporting | Reactive | Predictive, real-time alerts |

| Rework | 30–35% | Less than 10% |

| Client Approvals | 7–14 days | Less than 48 hours |

| Workforce Readiness | Unknown, fragmented | Centralized skills & certification tracking |

Cultural Transformation: The Real Differentiator

Digital leaders invest in the cultural and operational foundations that make digital adoption scalable and sustainable in the long run. Here are some examples that bring forth digital transformation in the field:

- Field crews trained and confident in mobile tools

- Standard digital workflows across regions and contractors

- Dashboards built into daily and weekly reporting rhythms

- A culture of data discipline, transparency, and accountability

- Managers using real-time insights to coach, prevent risk, and support team development

Digital transformation also strengthens retention and engagement by creating stability, visibility and clear paths for growth, critical in a sector competing for skilled labor.

TRC Accelerates Digital Transformation in Field Construction

At TRC, we help utilities and infrastructure owners modernize field operations with scalable, field-tested digital solutions designed for complex construction and T&D programs. Our approach minimizes disruption while ensuring maximum adoption, integrating mobile and cloud field data capture, digital QA/QC and safety workflows, real-time dashboards, predictive analytics, resource forecasting, connected collaboration platforms and workforce certification management. By enabling intelligence-driven, coordinated field execution, teams can plan, track and complete work more efficiently, safely and predictably across multi-regional projects.

Ready to Transform Your Field Operations? Contact Us

It ensures crews work from the latest information, flags issues early through automated alerts and standardizes inspections, preventing errors before they become rework.

Common tools include mobile inspection checklists, photo documentation, digital redlines, automated nonconformance logs and dashboards that track quality trends.

Real-time field visibility means stakeholders can see live progress, safety data and field conditions as work happens, enabling faster decisions and fewer delays.

Dashboards highlight safety trends, near misses and crew readiness in one view, helping teams identify risks early and prevent incidents proactively.

TRC provides engineering, project delivery, digital field execution and project controls support for T&D modernization, grid resiliency, renewable integration and major capital programs across North America, Europe, Africa, South Asia.

Adapt to

Change

Partner With TRC’s Tested Practitioners