Challenge

Roads, bridges, pipelines and most large-scale infrastructure projects all have something in common – the need for high-quality, high-accuracy fabrication inspection data. Issues in fabrication can cause negative ripple effects on a construction project from breakdowns in supply chain management to significantly delayed project timelines. Plus, most fabrication facilities for US projects are overseas, making constant communication and data exchange between the fabrication and construction teams even more challenging.

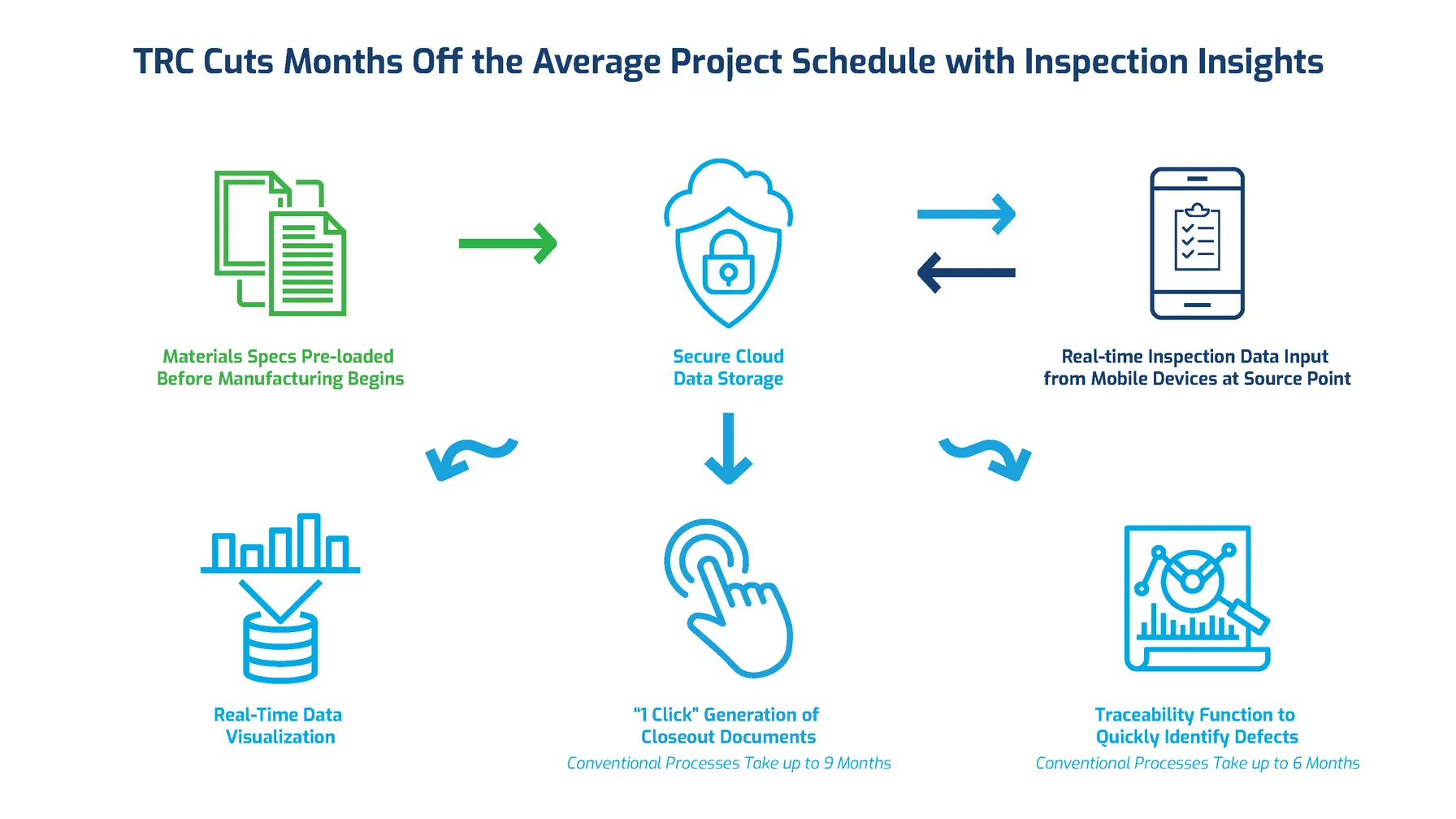

Accurate, timely and complete data is close to impossible with traditional fabrication inspection processes because data for each inspected piece of material is gathered inconsistently with no standardized process or centralized database. Inspectors could be collecting data on paper, via a spreadsheet or storing it on an individual device. When the time comes to consolidate data across individual inspectors at the end of a project, it can take months to compile and assemble into a final closeout document. All these challenges point to a need for more streamlined, trackable and real-time insights to align fabrication and construction schedules.

TRC provides real-time data and comprehensive dashboards to trace defects in minutes vs months and reduce the closeout documentation process from nine months to one click.

Solution

Inspection Insights enables inspectors to collect data via mobile devices at the source point throughout the fabrication process. This data is entered into templatized, electronic inspection forms and uploaded in to a centralized database on AWS. The day a piece of material is tested, the inspection data on it is immediately viewable. Collaborative, real-time dashboards foster improved schedule management and communication, more advanced materials tracking and forecasting, and weekly reports with benchmark data for operational enhancements.

Inspection Insights for Construction Management

Inspection Insights enables fabrication inspectors and construction managers to collect data on mobile devices at the source. Once a piece of material is tested, the inspection data is immediately uploaded into a cloud database to be analyzed for potential impacts on the fabrication schedule and the overall project design and construction schedule.

Result

Real-time data and comprehensive dashboards allow teams to diagnose defects or delays quickly and accurately – before a systemic problem develops. If there is a question of quality, the impacted piece of material can be identified or tracked in a matter of minutes. Tracing defects can take up to six months with more traditional inspection management processes.

Collecting data throughout the fabrication process greatly reduces the time to generate closeout documents – making it a one-click process. All stored documentation is seamlessly combined into a single report, which can reduce the closeout process by up to nine months.

By The Numbers

0

Click to compile & deliver closeout documents

0

Months less of inspection documentation

0

Months saved in troubleshooting defective materials