Whether it’s treating an arsenic spill at a railroad site in Wisconsin or releases of chromium and other metals or metal-cleaning solvents at manufacturing sites in California, New Jersey, and South Carolina, a mineral marrying iron and sulfur -iron sulfide- is emerging as a powerful and versatile tool in the environmental remediation toolbox.

Presenting at last month’s RemTEC Summit in Denver, I and my colleagues Lee Hovey and Dr. Bob Stanforth shared success stories about engineering biotic and abiotic mechanisms to promote the formation of iron sulfide minerals. The in situ biogeochemical transformation processes supported by these reactive minerals have been shown to degrade or stabilize various contaminants at the laboratory and field scale, and we are excited to be applying this technology to real-world remediation projects.

In one of our most successful applications, we injected dry cheese whey (read: mac-and-cheese powder) into the ground to promote in situ bioremediation, thereby enhancing sulfate and iron reducing bacteria. Capitalizing on the naturally existing geochemistry at the site, specifically elevated concentrations of sulfate in groundwater and ferric iron in soil, these bacteria produced metabolic byproducts that appear to have combined to form iron sulfide particles. The positive effect of iron sulfide minerals breaking down tetrachloroethene (PCE) continued for months after the enhanced in situ bioremediation (EISB) amendment injections had waned in effectiveness. Within the treatment area, concentrations of PCE decreased by at least one order of magnitude.

At the Wisconsin site, arsenic levels in marsh pore water samples came in as high as 300 milligrams per liter (mg/L), more than 2,000 times the level requiring remediation. TRC designed a solution that involved adding biodegradable organic carbon plus ferrous sulfate (a chemical precursor of iron sulfide that millions of Americans take as a treatment for anemia). Within just two months, arsenic levels had been reduced to below the remediation threshold. Similar remediation successes were observed at sites in New Jersey and South Carolina with Hexavalent Chromium [Cr(VI)] concentrations between 10 and 1,000 mg/L. Ferrous sulfate and calcium polysulfide were injected at the New Jersey site to generate FeS in the subsurface, and FeS slurry was directly injected at the South Carolina site. Cr(VI) reductions between 80 and 99.9% were achieved at both sites in a matter of weeks.

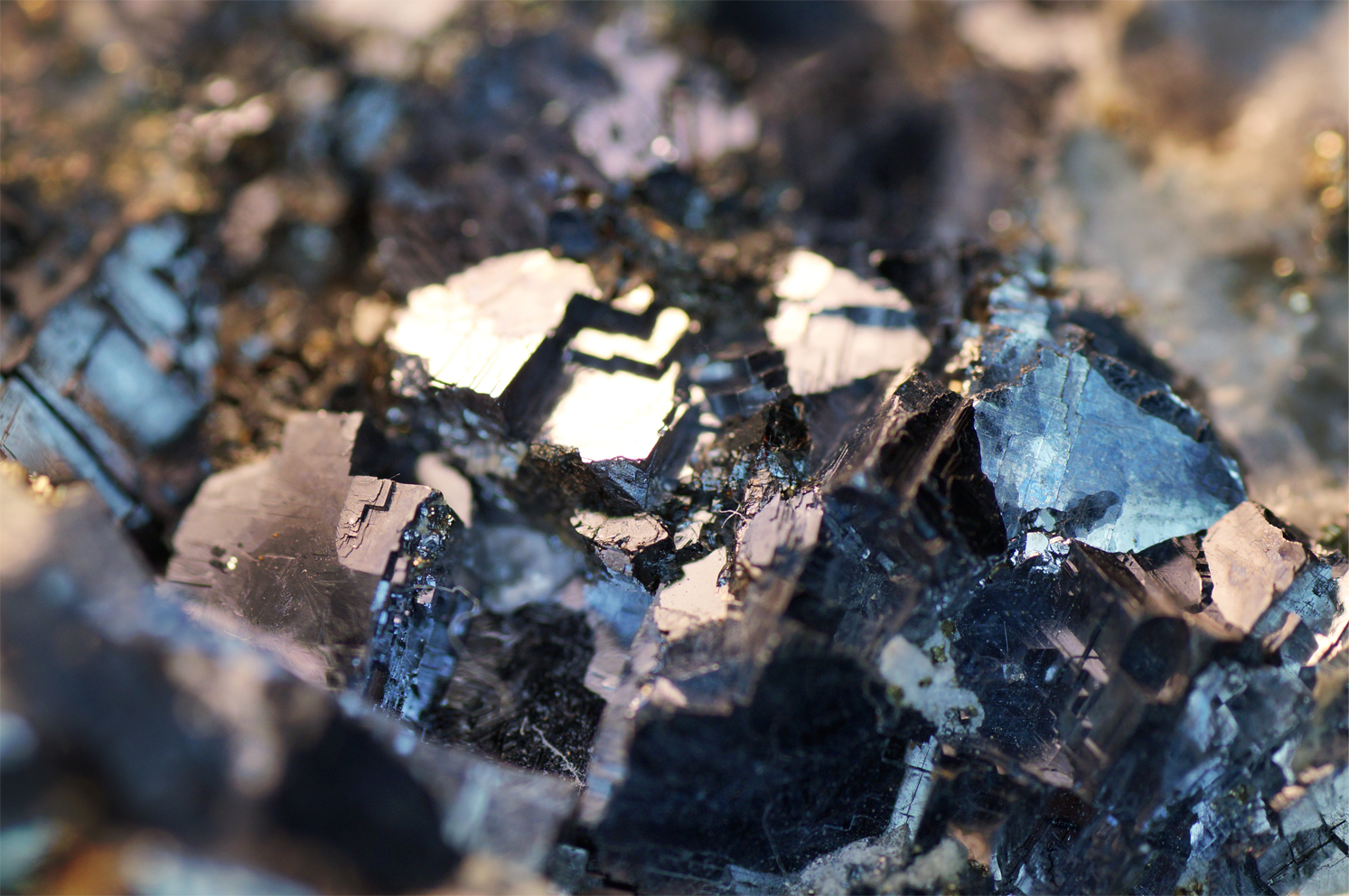

Iron sulfide may be produced by natural processes, or its production may need a boost in the form of added amendments containing iron, sulfate, and/or organic carbon. Looking to the future, we hope to further optimize amendment design given site-specific geochemistry, gain a better handle on predicting iron sulfide reactivity over time, and test different methods for evaluating the distribution of iron sulfide minerals in the subsurface on a micro- and macroscale. While we’re still working to fully understand and quantify the processes, what’s clear is that when biology and chemistry can be combined and iron sulfide is one of the results, the impact in remediating a wide range of contaminated sites can be significant and cost effective.

Thanks to my colleagues Dr. Robert Stanforth, Elizabeth Schwartz, Lee Hovey, Ross Surrency, David Lennon, John Trompeter, Brendan Lazar, Dr. Yasemin Kunukcu, and Brian Ross for their significant contributions to projects where we are pioneering iron sulfide remedies. For more information, please download our poster presentations below, or contact me.