As global efforts aim to reduce greenhouse gas (GHG) emissions, carbon management, inclusive of Carbon Capture, Utilization and Storage (CCUS), stands out as a critical technology when it comes to meeting long-term climate and energy goals. While conventional and renewable energy sources continue to support our global energy mix in the near term, CCUS offers additional emission reduction opportunities required to meet longer term goals.

Like any technology, CCUS comes with challenges. CCUS can be a safe and effective solution for reducing the concentration of carbon dioxide in the atmosphere if the risks are thoroughly assessed and appropriate steps are taken to mitigate them. With the support of practitioners experienced in the range of professional, technical and engineering services these projects require, organizations can leverage this important technology to help advance energy diversification objectives.

What Is Carbon Capture, Utilization and Storage (CCUS)?

CCUS traces to the early 1970s when carbon dioxide was used for enhanced oil recovery in oil fields nearing the end of production. Today, it is viewed as a critical technology in the global reduction of carbon emissions. It is widely recognized that fossil fuels will remain an important component of our energy mix as we diversify it. Because CCUS supports the continued use of fossil fuels while reducing CO2 accumulation in the atmosphere, it helps manage greenhouse gas emissions as renewable and sustainable energy sources are developed and integrated into our complex energy system.

Technological Approaches for Capturing Carbon

There are three broad approaches for capturing carbon from point and non-point emission sources:

- Post-combustion carbon capture (point source): Carbon dioxide emissions are captured from an emission source that combusts fossil or biomass fuels. The captured CO2 is conditioned to remove moisture and impurities to allow the safe and efficient transport – and ultimate storage – of the captured CO2.

- Pre-combustion carbon capture (point source): Typically, the hydrocarbon or biomass fuel is pyrolyzed to create a syngas, which is a mixture of hydrogen and carbon monoxide. The syngas is further processed to yield a mixture of hydrogen and carbon dioxide, from which the carbon dioxide is separated while the remaining hydrogen is burned as fuel in an Integrated Gasification Combined Cycle (IGCC) power plant. Again, the captured CO2 is conditioned to remove moisture and impurities before transport and storage.

- Direct Air Capture (non-point source): Carbon dioxide is captured directly from the atmosphere and conditioned to remove moisture and trace impurities.

The following table provides a high-level comparison of these three capture technologies.

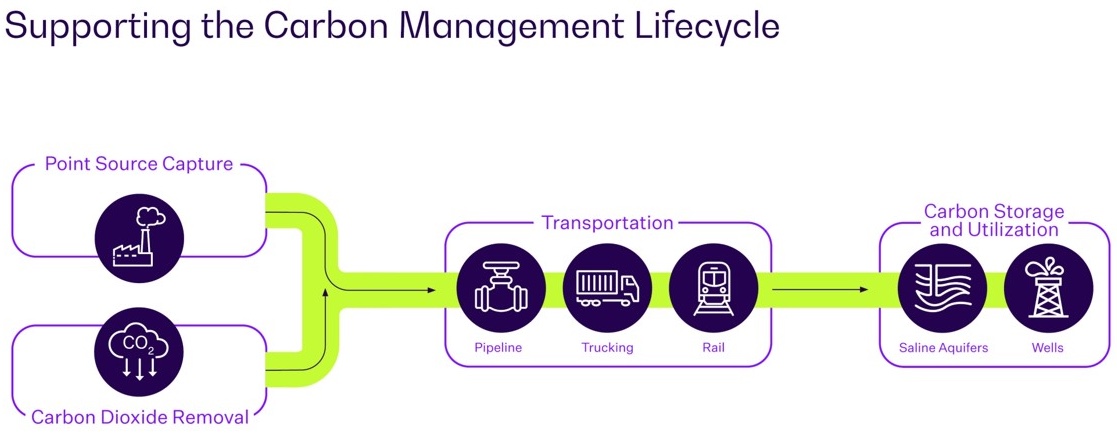

After Carbon is Captured

After carbon dioxide is captured, some level of processing is required to prepare it for transport and utilization and/or permanent storage. Post-combustion carbon capture requires the most processing while direct air capture requires the least. Transportation options commonly include pipelines, trucks, and railcars. Permanent storage options can include injection into underground geological formations or the production of biochar for use as a soil amendment. Utilization options can include enhanced oil recovery, beverage carbonation, or commercial greenhouse atmosphere enrichment.

Importantly, federal legislation supports CCUS development through a tax credit of $85/metric ton for captured CO2 that is either utilized or permanently stored, or an enhanced tax credit of $180/metric ton for captured CO2 from direct air capture technology.

Related Services

Managing Risk in Carbon Capture and Storage

Like any complex technology, CCUS comes with risks, but they’re manageable with the right systems in place. Risks vary based on storage and utilization options as well as the transportation mode. For example, geological sequestration of carbon dioxide includes leakage risk and potential seismic disruptions; however, these risks are significantly reduced and effectively controlled by the robust permitting and monitoring processes for storage reservoirs.

Ensuring Safety

While carbon dioxide can be transported in several ways, approximately 85-90% of industrial carbon dioxide in the US is transported by pipeline. There were approximately 5,300 miles of CO2 pipeline in the US in 2020 and that network is estimated to grow approximately 13-fold by 2050 to transport the captured CO2 required to manage GHG emissions.

Although there have been important CO2 pipeline incidents in the US, CO2 pipelines are safe. From 2004 to 2022, CO2 pipelines had an average accident rate of 0.001 per mile in operation per year. This safety record is due largely to robust CO2 pipeline safety regulations found at 49 CFR Part 195, Transportation of Hazardous Liquids by Pipeline, which are currently under review for enhancement.

The Underground Injection Control (UIC) permitting process for Class VI wells used for the geological storage of carbon dioxide is designed to ensure proper selection, safe operation and ultimately, secure and permanently close the storage facility. Proper site selection, adequate well design and state-of-the-art monitoring systems are crucial in ensuring the safety and stability of CCS projects.

Effectively Managing Emissions

CCUS is one of the most effective tools available today to manage GHG emissions. It allows for emissions reduction without sacrificing energy reliability, making it a powerful complement to existing technologies. As the regulatory landscape, tax incentives, and infrastructure continue to evolve, organizations that take proactive steps in CCUS development will be best positioned to meet long-term sustainability challenges.

Navigate Carbon Capture and Storage Projects with TRC

Although CCUS is not new, successfully designing and implementing projects can be challenging. TRC can help you navigate all stages of carbon management beginning with planning support, permitting and performance testing of carbon capture systems and continuing with the design, engineering and permitting of integrated carbon dioxide pipelines and supporting UIC Class VI well operators during the feasibility evaluation, permit application and operational phases of Class VI wells.

Contact us today to learn more about maintaining profitability while achieving your sustainability objectives.